Testing

The importance of reliability in Through Penetration Firestop Seals cannot be overstated. All Elasta-Seal® fire seal systems have undergone repeated tests which have established their performance for fire resistance, lower surface temperature on the unexposed side of the fire seal and passing repeated high pressure hose stream tests while at elevated temperatures.

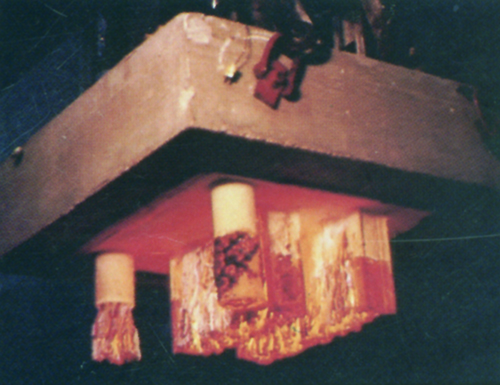

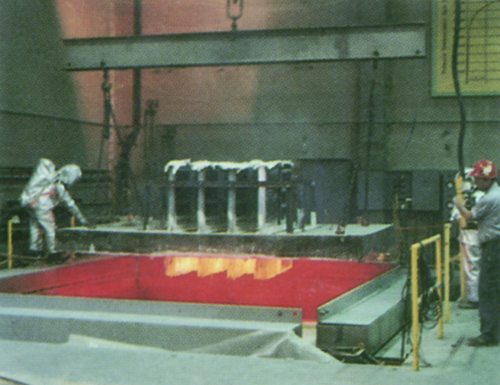

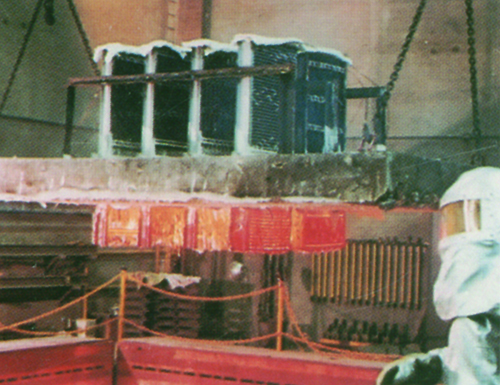

All recognized penetration fire seal tests are conducted in accordance with procedures outlined in ASTM E814. The furnace temperature for these tests exceeds 1900°F (1035°C). All materials (i.e. cables, trays, pipes and sealing parts) on the exposed side of the fire seal are glowing an incandescent red, as illustrated in the pictures below. These pictures were taken right after the test slab containing the fire seals was raised from the floor furnace by an overhead crane. From the floor furnace, the test slab is moved to the hose stream testing area and may undergo as many as three separate hose stream tests. Some of these are shown in pictures below.

All Elasta-Seal® parts, Type 310 Fiber Panel, Type 310 Fiber, Type 400 Fiber Panel, Thermalastic® 83 primer firestop coating, Thermalastic® 83E finish firestop coating and Type 4300 Caulk are Underwriters Laboratories - UL Classified “Fill, Void or Cavity Materials”and Underwriters Laboratories of Canada - ULC Listed “Firestop System Components”. These have passed the IEEE 634 standard for fire resistance, unexposed surface temperature requirements and hose stream resistance. Please refer to the current UL and ULC guides for specific systems’approvals related to tests we conducted at UL.